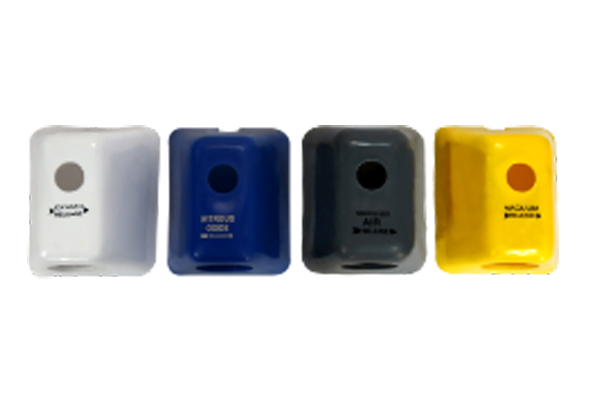

SELF SEALING VALVES (SCHRADER TYPE)

These feature self sealing outlet points that allow gases & vacuum to be drawn and also feature use of noninterchangeable outlet fittings. Here, the supply is provided through insertion of appropriate safety key plug into orifice of outlet point and locking the same into desired position. Further, for breaking connection, milled collar of orifice is rotated few degrees to right that result in safety key plug being automatically ejected and cutting off of the gas flow. Self Sealing Valves are available in Oxygen, Nitrous, Air and Vacuum.

|

Code No. |

Product Name |

|

1704 |

SELF SEALING VALVE OXYGEN |

|

1705 |

SELF SEALING VALVE NITROUS OXIDE |

|

1706 |

SELF SEALING VALVE AIR |

|

1707 |

SELF SEALING VALVE VACUUM |

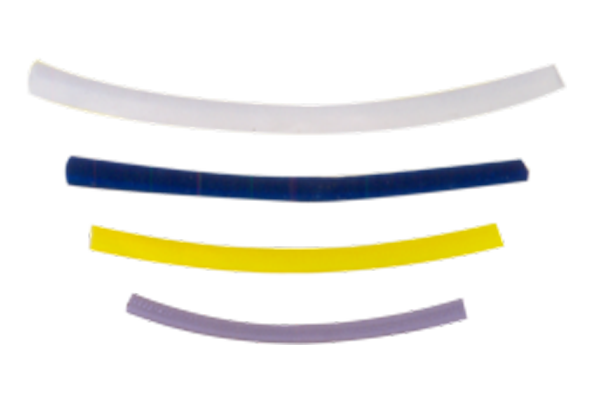

SAFETY KEY PLUG (SCHRADER TYPE)

The Plug Safety Key finds application in opening self sealing valve for drawing gas from pipe line and its removal automatically cuts off the flow of gas. Further, the plug safety key is designed in different finish types for handling the demands of different input gases including Vacuum, Air, oxygen, Nitrous oxide.

|

Code No. |

Product Name |

|

1708 |

SAFETY KEY PLUG OXYGEN |

|

1709 |

SAFETY KEY PLUG NITROUS OXIDE |

|

1710 |

SAFETY KEY PLUG AIR |

|

1711 |

SAFETY KEY PLUG VACUUM |

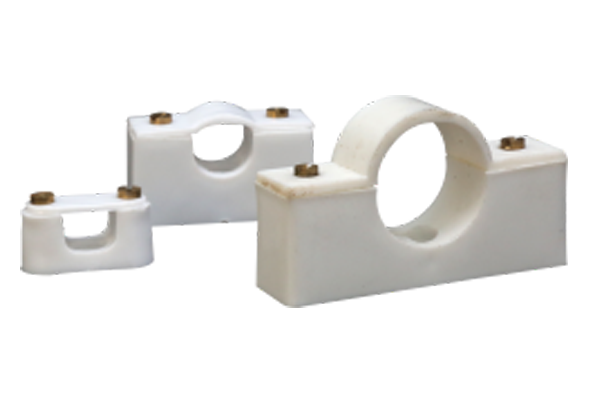

PLASTIC COVERS FOR SELF SEALING VALVES

|

Code No. |

Product Name |

|

1716 |

‘S’ BRACKET |

|

1718 |

PLASTIC SADDLE CLIP – 10MM |

|

1719 |

PLASTIC SADDLE CLIP – 16MM |

|

1720 |

PLASTIC SADDLE CLIP – 28MM |

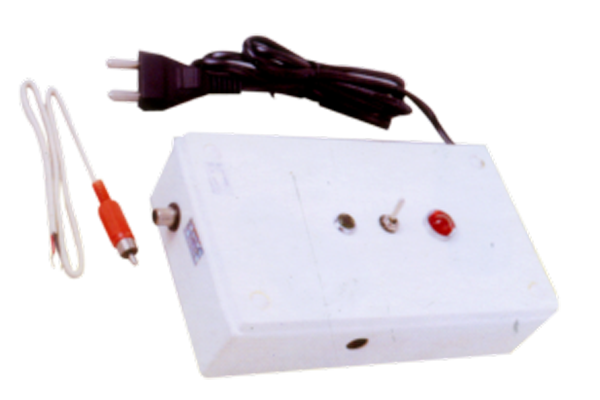

MINIMUM CONTACT GAUGES & GAS FAILURE ALARM FOR PIPELINES

The contact gauge has electrical contacts. It should be connected to the pipeline gas failure alarm which has two signal lights, a buzzer & an “ON/OFF” switch. When the contact gauge is connected to the power supply and the ON/OFF switch of the alarm is switched “ON”, green light will show indicating that the electrical supply serving the contact gauge & alarm are working correctly. The green light should show at all times when the pipeline is in use. The other signal light viz red is a warning light which automatically shows & the buzzer rings when the pressure in the running cylinder has fallen to a determined value. Put the switch to “OFF” position after which the reserve cylinder should be brought into operation promptly to ensure continuity of supply.

VACUUM REGULATORS

Airways’s range of vacuum regulator represents the ultimate in vacuum control. Vacuum Regulator for High Suction – 0 to 760mm Hg offered comprises Airways’s Vacuum Regulators that are precision designed to provide for ultimate vacuum control support. These vacuum regulators are designed to cover all involved medical central pipeline applications as required in operation theatres as well as in wards. Further, the regulator also comprises polymer body that houses ON/OFF lever as well as adjustable knob at fronts with diaphragm so as provide for optimum suction control. Further, these also come with vacuum gauge with different scale options depending on model being used.

VACUUM UNITS (WITHOUT REGULATORS )

Vacuum units are available in 600, 1000 & 2000. The jars are made of polycarbonate, practically unbreakable, shatter resistant and autoclavable at 134 C. ABS is used for other components to withstand hard usage and provide trouble free service over a long period of time. A stainless steel bracket is provided on the cap as a separate component and not as an integral part of the cap to avoid the cap breaking, when the jar gets filled with suction fluids. The bracket fits directly on the mounting bracket on the wall. A well proven fluid control trap fitted on the unit automatically and efficiently shuts off vacuum fully, preventing the transfer of liquid to the vacuum regulator, pipeline and pump.